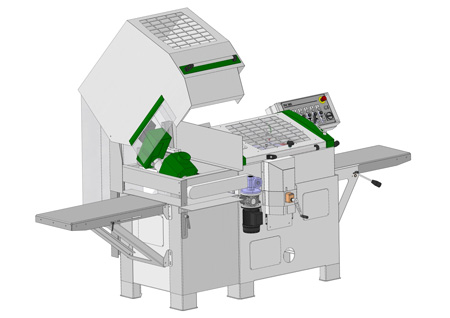

PH360 Foursided Planer/Moulder

PH360

Foursided planer/moulder

Large capacity

Planes and moulds

on all four sides in one pass

Built in planer function

Stainless for use

in cold rooms or outdoors

Horizontal cutter can give 4 functions

5 motors

Stepless feed using planetary gearbox

The size and weight

makes it portable

Feed system that can handle timber

with a lot of resin and also fresh wet

timber.

Extremely easy to adjust

Adapted to a very large

range of standard blades and cutters with

reasonable prices

The machine works:

- In carpentry

- At the sawmill

- On the farm

- In industry

- In construction

We have manufactured and developed

4-sided moulders since 1993

Capacity:

360 mm width and 130 mm height

Planing and moulding can be done on all four sides.

Planing width with and without profiling, 510 mm

Robust, strongly built, 675 kg.

High engine power, a total of 16 kW or 22 HP

Input table with planer function with rapid adjustment of the chip thickness of both the bottom and right side.

Planer table, cast iron, is in a fixed position regardless of the size of the work piece.

Cutters 410 mm wide, for planing function.

Vertical cutter right. for planing function.

Vertical cutter left adjustable with digital counter with reset function.

Cutter is 510 mm wide, for thicknessing.

Digital readout of the height

The chip hood of the cutter can be optimized to the work piece

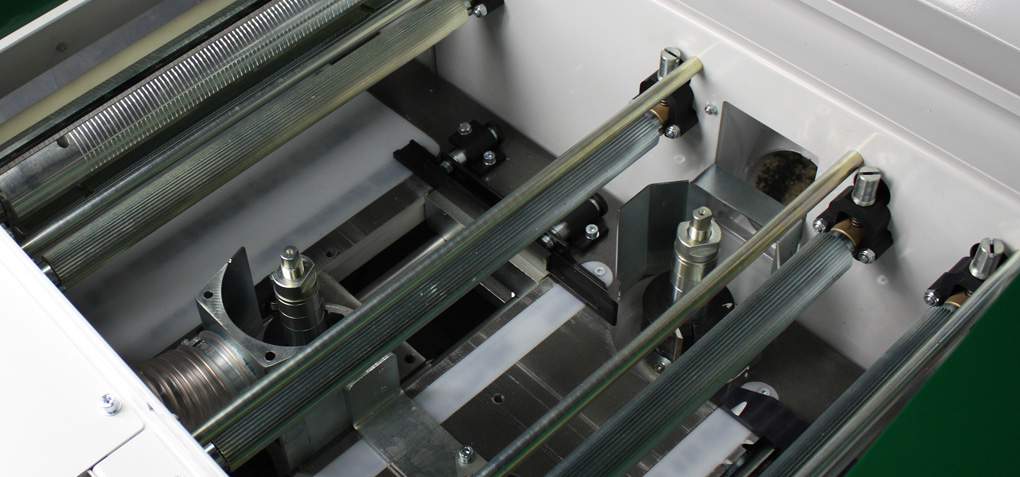

The machine has 5 pc feeding rollers

throughout the machine.

The machine is fitted with variable feeding between 3-15 m / min. Can alternatively be fitted with higher speed to 60-30 m / min.

A planer for efficient planing.

PH360 planes and profiles four sides in one pass. Gives good results with high quality, finish and with, perfect measurement.

The machine is easy to adjust; you can re-set profiles and dimensions in a matter of minutes It is therefore suitable for the rapid production of planed wood in larger and smaller series.

Making it perfect for:

The joinery for the manufacture of furniture components,

windows, frames, etc. thanks to its capacity and

rich moulder function

In the sawmill for the manufacture of smaller strips up to floorboards

and beams.

On the farm for renovation, expansion and sale.

The major industry of specialized and smaller series, thanks to the

is easily adjustable and economical for these series sizes.

In building its capacity from small bars to large profiled beams and timber blocks. When special profiles and even smaller series needed.

It could also can be used in place because it is removable.

Large capacity.

The machine has a large capacity, up to 360 mm wide and 130 mm high at the four-sided planing/moulding. For two-sided planing is the

height 230 mm width 410 mm

-Sided planing and after assembly, the entire 510 mm planing width used in

a maximum height of 230 mm.

At same time you can also mould.

Profile depth and cutting depth are also impressive.

Cutters

For vertical cutters, the machine has two spindles

30 mm diameter and 130 mm height. This means that there is a wide range

of tools on the market.

Side cutters come with as standard. Thus, the machine

ready to dimensional planing and for moulding it is only necessary

to add profile knives.

Horizontal cutters can be set up with 4 functions:

-planing with 2 blades

-planing with 2 blades and moulding with 2 profile blades

-moulding with 4 profile blades to combine 2 different profiles

-planing with 4 blades for even a better finish

All cutter blocks can use moulding cutters and we have a large selection of profiles. You can also have them custom design.

Feed

The machine has 5 feeding-rollers. The last feeding roller is made with a polyurethane coating for good grip, long life, and without affecting the planed surface.

Five motors

All four cutters and feed powered by separate motors, with on and off button. The control panel all buttons and with indicator lights are easily available.

Built-in switch for chip extractor or 5th cutter.

Controlled from the control panel

Clear and adapted to a fifth universal cutter

Of course, machine has cast iron table for stability, precision and durability.

TECHNICAL DATA

Wood Dimensions

4-sided planing

Max width 360 mm

Height 10 to 130 mm

2-sided planing

Planing width 410 mm

Height 10 to 230 mm

Planing (requires assembly)

Planing width 510 mm

Height 230 mm

Upper horizontal cutter

Diameter 88 mm

Width 510 mm

Power 5.5 kW (7.5 HP)

Speed 6000 r / min

Chip depth, max 8 mm

Profile depth, max 20 mm

Lower horizontal cutter

Diameter 72 mm

Width 410 mm

Power 4 kW (5.5 HP)

Speed 6000 r / min

Chip Depth 0-8 mm

Profile depth, max 10 mm (slot drill 15 mm)

Cutters Speed 6000 rpm

Vertical cutters

Spindle diameter 30 mm

Cutter Max 130 mm

Diameter max 140 mm

Power 3 kW (HP)

Side cutters Speed 6000 rpm

Cutting depth, max 30 mm

Included standardkuttrar

Type TB90 steel

Diameter, body 90 mm

Body height 40 mm

Cut, nature plan HSS

Cut 50 mm wide

Feed, planetary

Power 0.75 kW (1 HP)

Feeding speed 3-15 m / min or

6-30 m / min

Electrical System

Total power 16 kW (22 HP)

Electrical connection 3-phase, 16 - 32 A, 400V

Dimensions and weight

Length and width of 1970 x 1125 mm

Height 1430 mm

Weight 675 kg

ACCESSORIES

Steel and cutters are available in a separate catalogue.

Wheel kit

Four lockable castors. Replaces standard legs. 360-045

Longer fence (front) 1300 mm (standard 800 mm) 360-328

Longer fence (front) 2000 mm (standard 800 mm) 360-331

Shortened fence (front) 370 mm (standard 800 mm) 360-330

Rear fence extended 900 mm (standard 430 mm) 360-370

Lift mechanism for the first feed roller. 360-365

Used when planing of thin material.

Support roller

For placement on the in-or out-feed tables 360-371

For extra support and control

Chip extractor system

Chip extractor SP5000

Efficient fan of inclined and curved fan blades

The heart of the system. Burly fan. Impeller

in steel. Well balanced. Flow 5000 m3/hr.

Adapted for PH360

Outlet can be in several different directions.

Motor 4 kW (5 HP) Taking 1x250 mm. Exhaust 1x250 mm or 2 x 200 mm

Connection, 310-500

Exhaust 5x100 mm, 1x125 mm, 1x250 intake

Cyclone with filters and chip bags, 301-008

Complete with filter, cyclone, bag holder

Each unit has 2 filters and 250 l chip bags.

For connection to the chip fan SP5000 needed 2 units (4 filters and 4 chip bags)

Connection for 2 filter systems to the SP5000, 310-501

Taking square (adjusted to SP5000), exhaust 2x200mm

Fifth universal spindle

To the PH360 you can adapt a fifth cutter of universal type. The cutter can be set and work on all four sides. It can also be tilted up to 270 degrees.

The spindle can be shifted so that the shank cutters can be used. Spindle diameter is 30 mm. This provides a wide range of cutters to be used as well as brushes and grinding wheels. Handle tools with shanks up to diameter 20 mm can be used.

Technical data

Spindle, standard 30 mm

Spindle for shank router tools (optional) 1-20 mm

Maximum tool diameter 200 mm

Maximum tool height 130 mm

Spindle speed 3000, 6000, 9000 rpm

Spindle for shank routers 3000, 6000, 9000.14000 rpm

Movements of spindle:

Tilting 270 degrees

Operating height 500 mm

Lateral movement 350 mm

Motor 3-phase 400V (230V)

Power, motor 3 kW (4hk)

Weight 310 kg