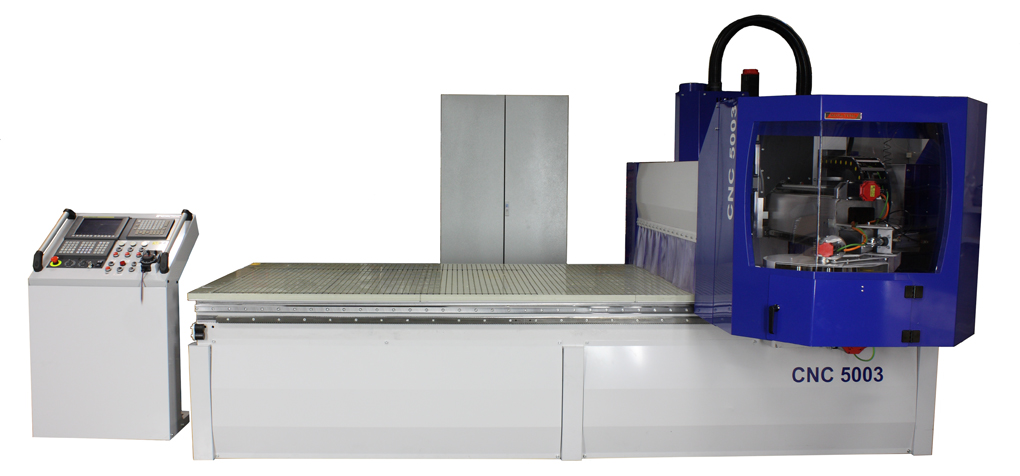

CNC5003

MOReTENs CNC5003

- Industrial Machine, which also fits the craftsman

- Combined machine can be equipped for a variety of operations

- Can be operated from three sides

- Industrial Control Systems, non-PC based

- Digital servos with high resolution for higher efficiency and less vibration

- Interface for PC and CAM software. Server built-in to the controller

- Movable control panel on wheels

- Portal design for better stability

- Dual-motor (2 servo motors) of the portal for maximum efficiency

- Combined vacuum table for both boards and solid wood. Can be used in four ways:

Directly on the table with rubber sealings

On the table with an intermediate sheet of MDF. The vacuum goes through the sheet.

With vacuum gear directly on the grid table (Then use the vacuum in the table)

With vacuum gear on an intermediate disc (vacuum comes from separate tubes)

- Can be customized

- Large variety of accessories

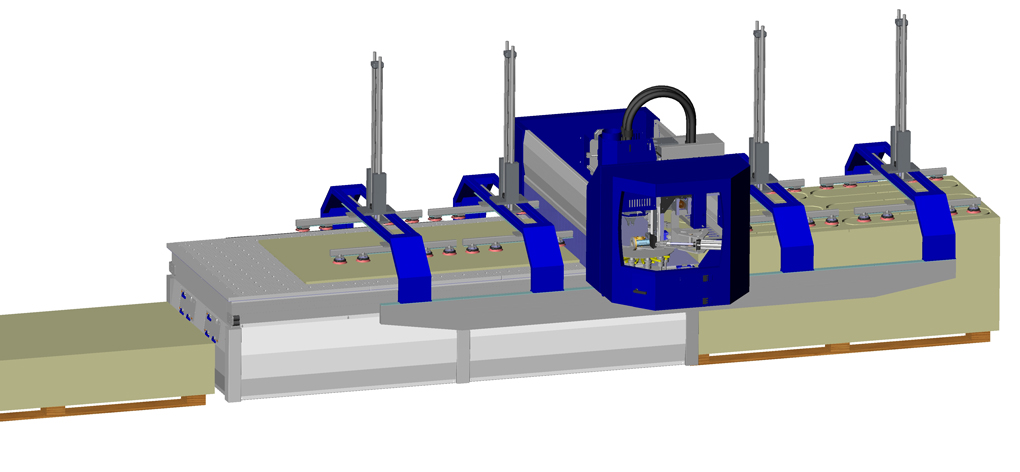

- Can be equipped with integrated material handling

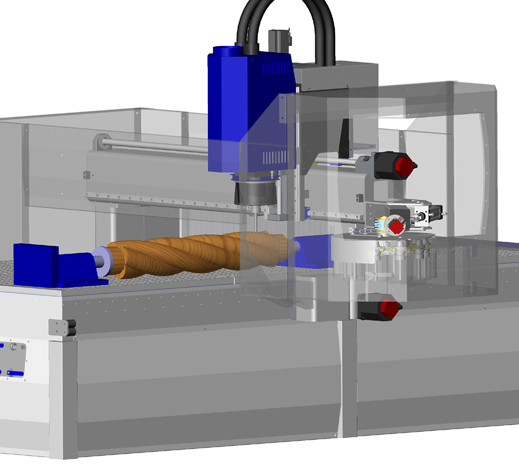

- Milling-turning equipment on tables are available. For example, rifle butts

- Also available in 4-axis and five-axle design.

CNC5003 is an industrial machine that also fits the craftsman. The machine is

specifically designed for wood, boards, plastic and aluminum.

The craftsman requires a machine with an easy operation and maintenance.

The industry requires the machine stable and efficient construction, precision

and the opportunity for customization.

Programming

The control system is programmed with G-code (ISO code) The machine is also prepared for CAM systems.

Vacuum Table

The table is a combination table for all kinds of details and materials.

- Combined vacuum table for both boards and solid wood. Can be used in four ways:

Directly on the table with rubber sealings

On the table with an intermediate sheet of MDF. The vacuum goes through the sheet.

With vacuum gear directly on the grid table (Then use the vacuum in the table)

With vacuum gear on an intermediate disc (vacuum comes from separate tubes)

The table is organized in 8 main segments where each segment is manually operated

.

In each segment there are eight vacuum points. (Total 64 points) To be sealed to vacuum only where needed.

Aluminum Table

Flat table in aluminum are available as accessories

Spindle Motor

Spindle motor is selectable between type, size, and number.

Standard spindle motor

Our standard spindle motor, the tool change with cone HSK63. Spindle is controlled steplessly with a drive and have a speed between 300 to 24,000 L / min. Spindle motor has ceramic bearings.

Accessories, optional

Machining Spindles

The machine can be equipped with a number of spindle motors, both vertical and horizontal.

4-axis controlled

Fourth axis controlled and programmable 0-360 gr. C-axis for example, controlling the angle unit

Milling-turning with 4-axis

You place the workpiece as in a wood turner and positions the lathe spindle.

For complex parts as rifle butts, rococo legs, columns, etc..

CAM software

We offer a variety of CAM software for your business.

Vacuum gear

Vacuum gear available in several versions.

Angle Units

Angle Heaters for sawing, milling, drilling, etc. with horizontal spindle.

Drill head

There are 11 pieces of various drill heads to choose from 7 pc to 25 pc spindles

Each spindle is separately controlled.

Laser

Laser to help to place the material. From simple cross-lasers for advanced laser projectors that shows a picture of the part to be manufactured.

Material Handling

In industrial production, the efficiency is increased further with an integrated

material handling equipment. We equip the machine with a modular system that adapts to your needs.

Machine Protection

Protection around the machine as such. gates, light curtains

Aluminum Table

Aluminium table to use fixtures that are screwed into the table. For example.

aluminumbearbetning.

TECHNICAL DATA

Bold text = standard

X-axis, length, 2500 mm 3080 mm 5080 mm 8000 mm

Y-axis, lateral, 1 250 mm 1540 mm 2050 mm

Z-axis, height, 200 mm 400 mm 600 mm

Speed

X-axis 60 m / min

Y-axis 30 m / min

Z-axis 15 m / min

Spindle motor with tool change

8 kW 12 kW

Kona ISO30, HSK63

Max speed 24 000 rpm

Tool change, rotation, included in the portal, number 10 pcs

Vacuum pump, power 4.0 kW 5.5 kW

Vacuum pump, flow rate 126 m3/hr 250 m3/hr

Negative pressure, maximum 0.9 bar

Frame size (footprint) 1550 x 3950

Total length 4050 mm

Overall width 2700 mm

Overall height 2200 mm

Weight about 3000 kg

CNC5003 är en industrimaskin som även passar hantverkaren. Maskinen är speciellt framtagen för trä, skivmaterial, plast och aluminium.

Hantverkaren kräver maskinens enkla handhavande och underhåll. Industrin kräver maskinens stabila och effektiva uppbyggnad,

precisionen samt möjlighet till specialanpassning.